3.2m Industrial Hybrid UV LED Printer

The integrated cable carrier system effectively minimizes motion-related errors, ensuring superior stability during operation. Automatic media thickness detection significantly enhances ease of use and overall user experience. With its excellent performance and wide compatibility, the M3300 helps boost production capacity, expand application possibilities, and stand out in today’s highly competitive market.

Key Features

Explore & Anticipate the Future

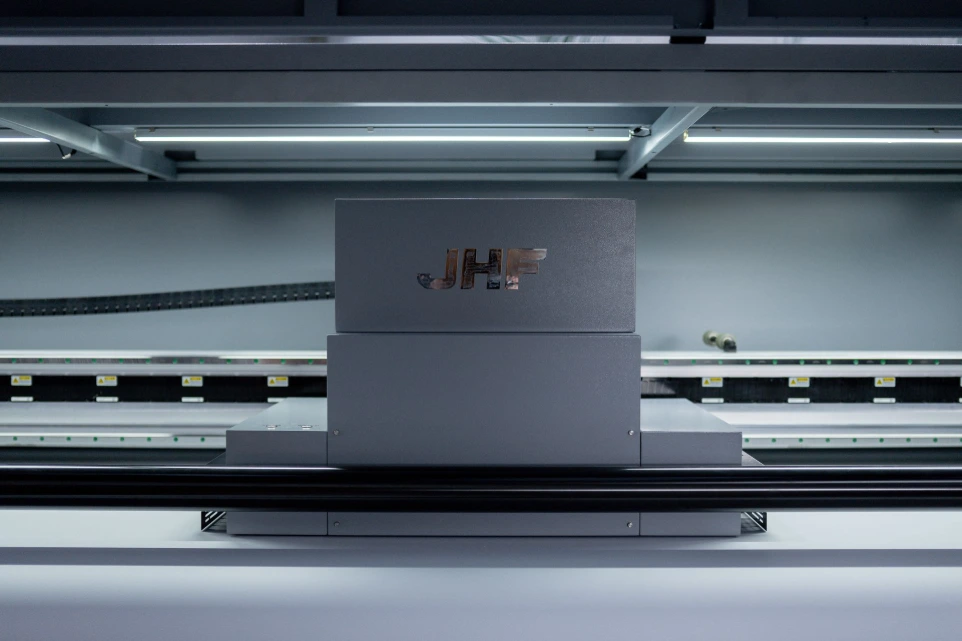

Built around the latest advanced printing concepts, this system integrates cutting-edge technologies to deliver outstanding performance. A high-precision metal linear motion system ensures fast, smooth, and highly accurate printhead movement. The constant-pressure vacuum table guarantees stable media hold-down, resulting in exceptional image quality and consistent print results.

Applications without Limits

UV LED printing supports an extensive variety of materials from flexible media like banners, films, and textiles to rigid substrates such as glass, ceramic tiles and acrylic panels, opening the door to countless application possibilities.

Texture Printing

The M3300 brings three-dimensional embossing to life, showcasing distinct layers with a realistic tactile experience. It supports variable embossing heights to meet individual design requirements, making it ideal for high-end art reproduction, custom decorative pieces and exhibition hall installations.

Core Technology

Switchable Feeding System

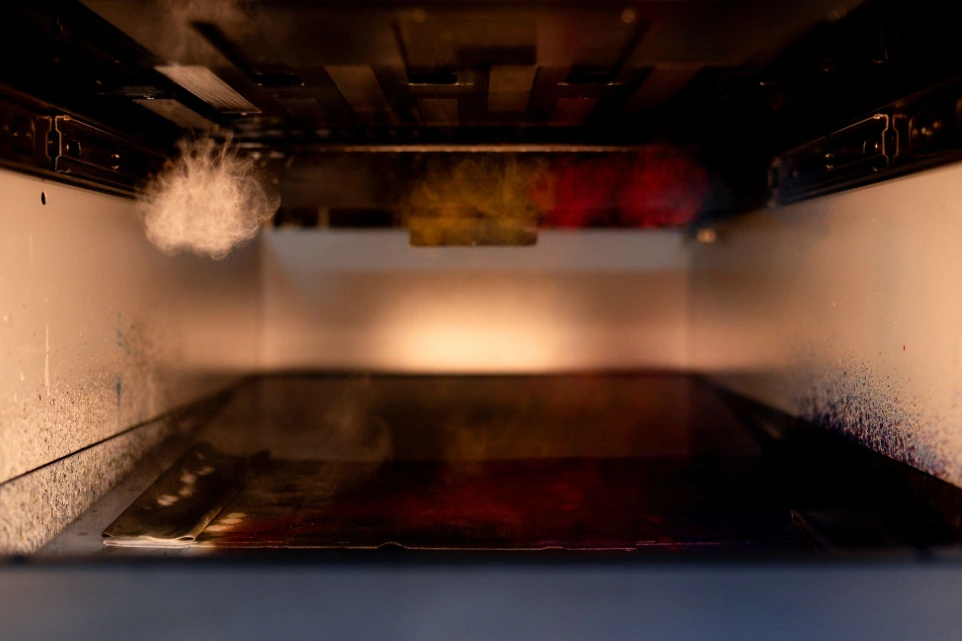

LED Curing Solution

Motion Failure Prevention

Advanced Ink Supply System

Consistent Material Hold

Color Management Software

High-Speed Printing

The Y-axis uses a high-quality rubber timing belt to guarantee accurate stepping without deviation, eliminating banding and print artifacts and ensuring consistently high-quality prints.

Let's Connect

Our experts are ready to assist you.