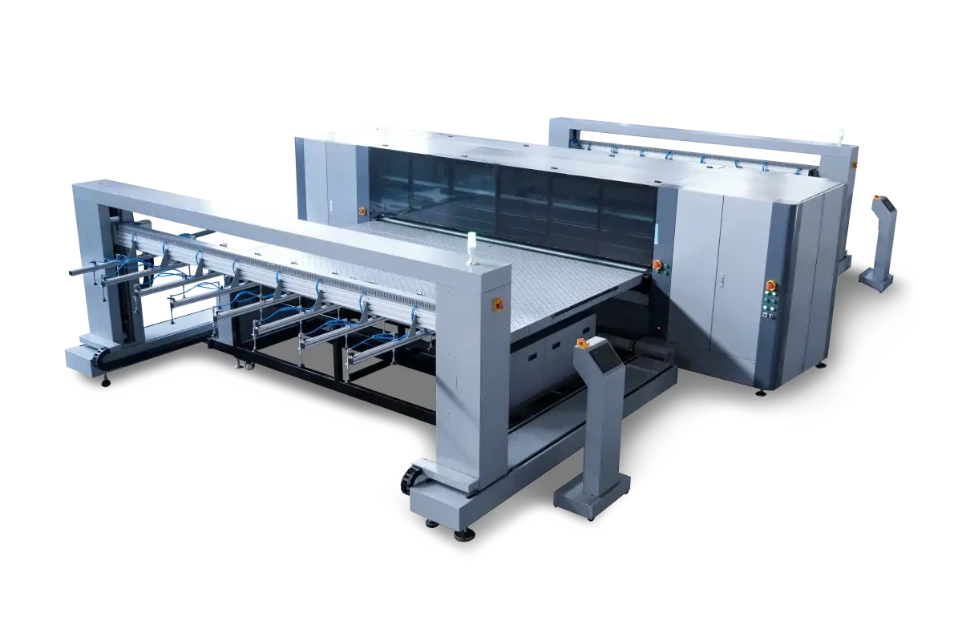

M3300-s Automatic Loading And Unloading Printer

The M3300-s is a fully automatic loading and unloading printer, independently developed by JHF. The entire process from loading and printing to unloading is fully automated, enabling continuous printing and significant boost in productivity. It effortlessly handles heavy, rigid boards and ensures precise positioning for a large-format sheet. The printer also supports simultaneous printing of multiple boards and allows seamless switching between different printing modes, adapting quickly to varying job requirements for maximum productivity.

Key Features

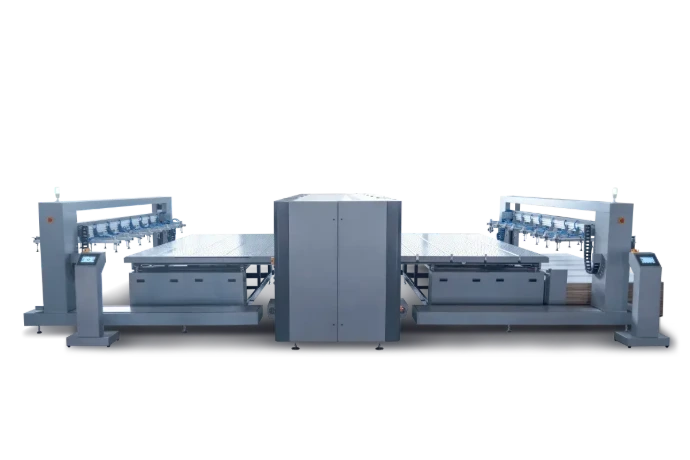

Automatic Loading and Unloading

Each suction cup provides a maximum holding force of 2kg. Multiple cups work in unison to easily handle heavy boards up to 60mm thick. This simplifies the workflow and offers greater flexibility in material handling.

Precise Positioning for Large-Format Boards

The system securely holds single boards up to 3200mm (W) x 2000mm (L), ensuring a flat, wrinkle-free surface without deformation. The board maintains a straight, stable path throughout the process, preventing any deviation.

Simultaneous Multi-Board Printing

Print up to 4 boards simultaneously (each with a maximum width of 800mm and a minimum length of 800mm) to meet custom requirements.

Uninterrupted Continuous Printing

The gap between boards is minimized to under 10cm. The printhead carriage does not stop during the transition between boards, enabling continuous printing to prevent production capacity waste.

High Image Precision

With a material feeding speed of 70 seconds per sheet, the printer produces vibrant colors and large areas with exceptional uniformity.

Core Technology

Automatic Loading & Unloading System

Board Separation Mechanism

Automatic Alignment Feature

Automatically aligns each board to prevent material displacement, guaranteeing consistent positioning and uniform quality across batch prints.

Industrial-grade PLC

Multi-Motor Centering Platform

Intelligent Safety Warning System

Equipped with visual and voice alarms, the system provides automatic alerts whenever the machine starts, keeping operators informed and safe.

Automatic Height Detection Function

Automatic Material Edge Finding & Multi-sheet Intelligent Layout

Precision Component Assurance

A combination of a 0.5 μm high-precision linear scale, a magnetic levitation linear motor system, and precision guides ensures consistent, stable, and highly accurate printing.

Negative Pressure Platform System

High-Efficiency Ink Curing System

Ink Temperature Control System

Equipped with reliable temperature control boards, this system maintains uniform ink characteristics regardless of environmental changes.

Let's Connect

Our experts are ready to assist you.